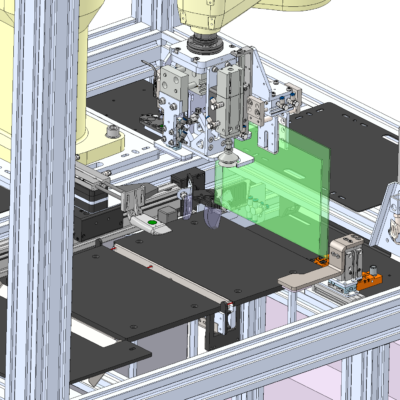

Automated Book Scanning Robot

Project

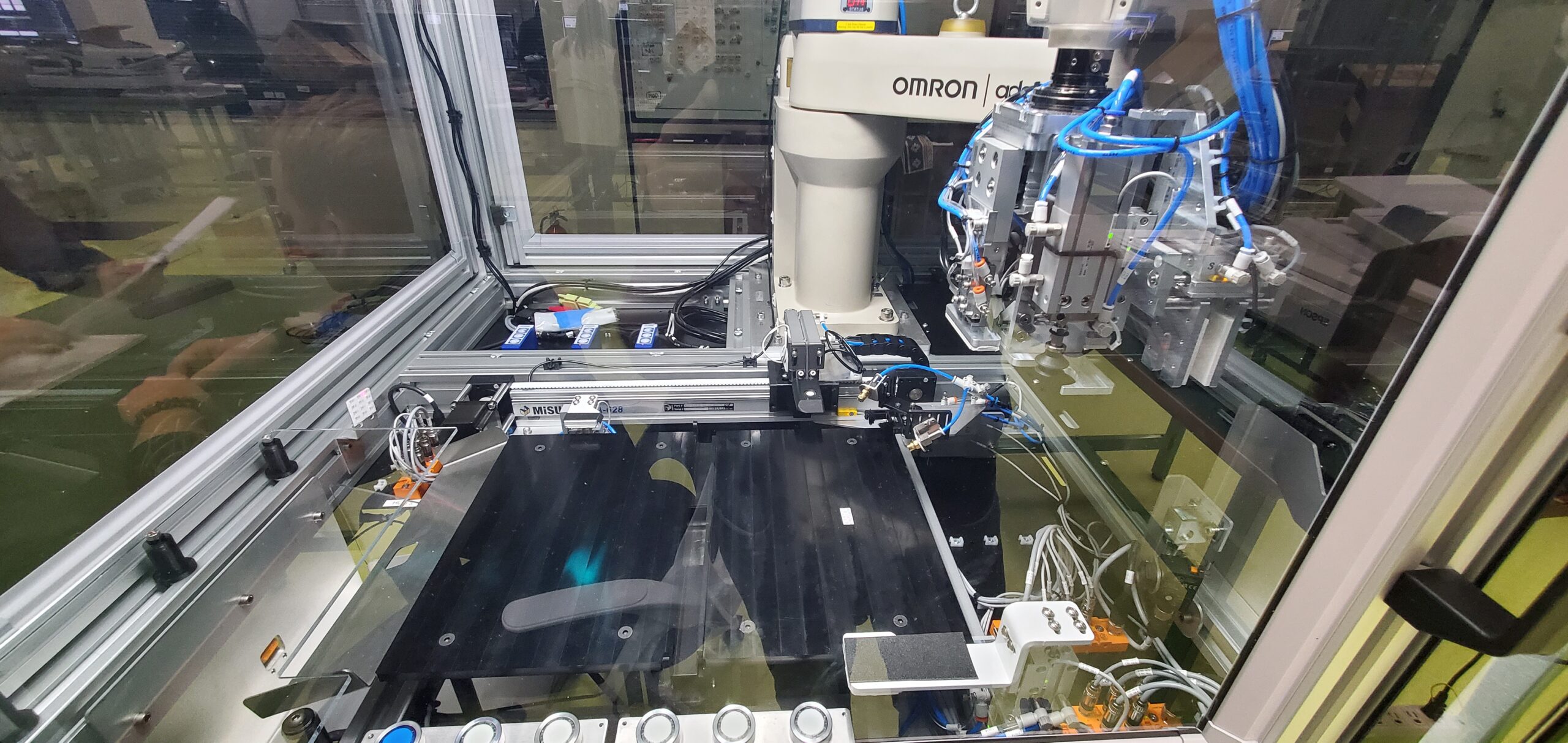

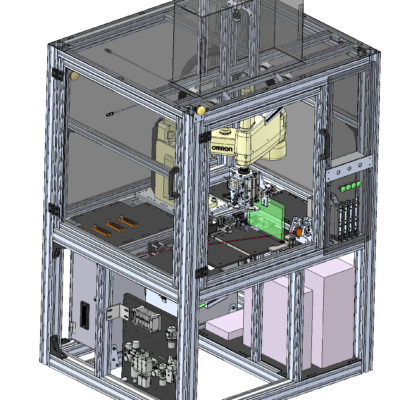

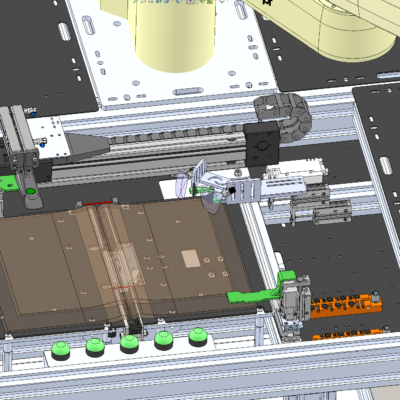

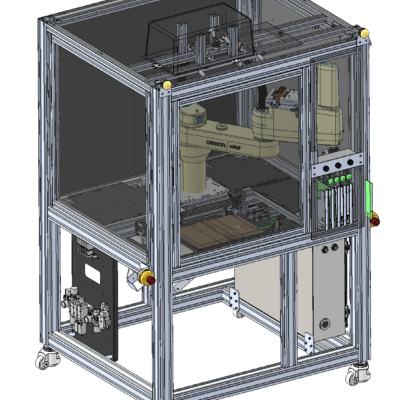

A prototype machine to automate book page scanning had previously been developed. In the following 7-month timeline, full production machines needed to be developed and deployed to a customer site. This includes full engineering development cycle time as well as manufacturing time. The customer wanted to see a throughput of approximately 1 page per 3-5 seconds.

Solution

With a 5-person team of contractors to help develop and validate current designs and refine them into a production-ready model, I was tasked with leading the team through engineering design development. This included developing a pilot machine to aid in the design direction of development.

This project required me to program the robotic arm with Adept ACE V+ software, a proprietary variant of C programming language. The actuator is operated by a Beckhoff PLC operating with TwinCAT software, another variant of the C programming language. While the original designs for the prototype were not generated by me, I was directly responsible for driving, refining, and validating (and in some cases redesigning) the production model designs for final production to meet manufacturability and cost goals.

Result

A pilot machine was built to validate the design direction for the project as well as allow for design refinement for final production. Two production robots were built, delivered, and deployed to a foreign country within the 7-month time window and within the development budget. The cycle rate of the machines delivered to the customer the appropriate throughput of an average of 1 page per 3 sec. This successful delivery helped secure further robotic project funding with this customer. These machines were to be delivered to a foreign country for continual use in support of document digitization efforts.

All media used with permission from parent company