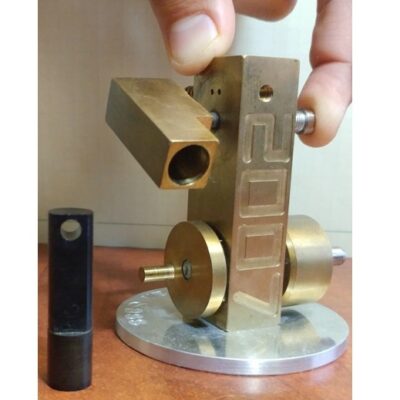

Manufactured Air Motor

Purpose

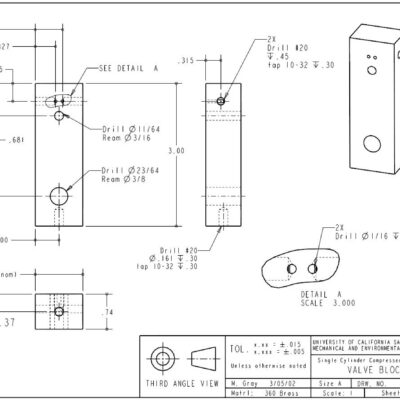

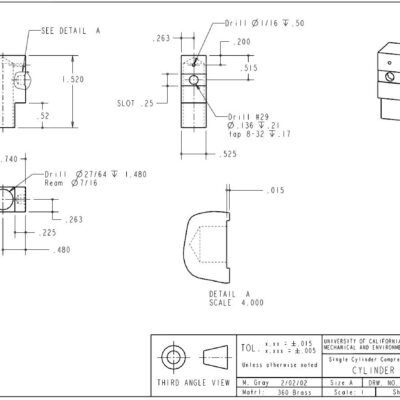

Make machined parts from dimensioned and toleranced drawings. Machine shop tools were used to create a piston-driven air motor that spins a flywheel when provided with pressurized air. This project gave me exposure to shop tools including mills, lathes, band saws, and taps. Although not the original intent of the project, this project also gave exposure to CNC machine operation as well.

The school project included a set of machine drawings to create the brass, aluminum, and plastic pieces shown. Simple instructions were provided for guidance in machining the parts correctly. Common machine measuring tools were used to ensure dimensions and tolerances were met.

Result

The level of precision machining is best demonstrated by how slow the air motor could spin. The finer the tolerance of the machined parts reduces excess friction from inaccurate tolerances.

After the successful completion of the initial project, relief and engraved lettering (UCSB and 2007, respectively) were machined to continue using the machine tools. The ‘7’ in 2007 required a CNC machine, so the basic operation of a CNC machine was learned as extra learning. After relief and engraving, the CNC machine was also used to engrave my name on the aluminum base of the motor.