Portfolio

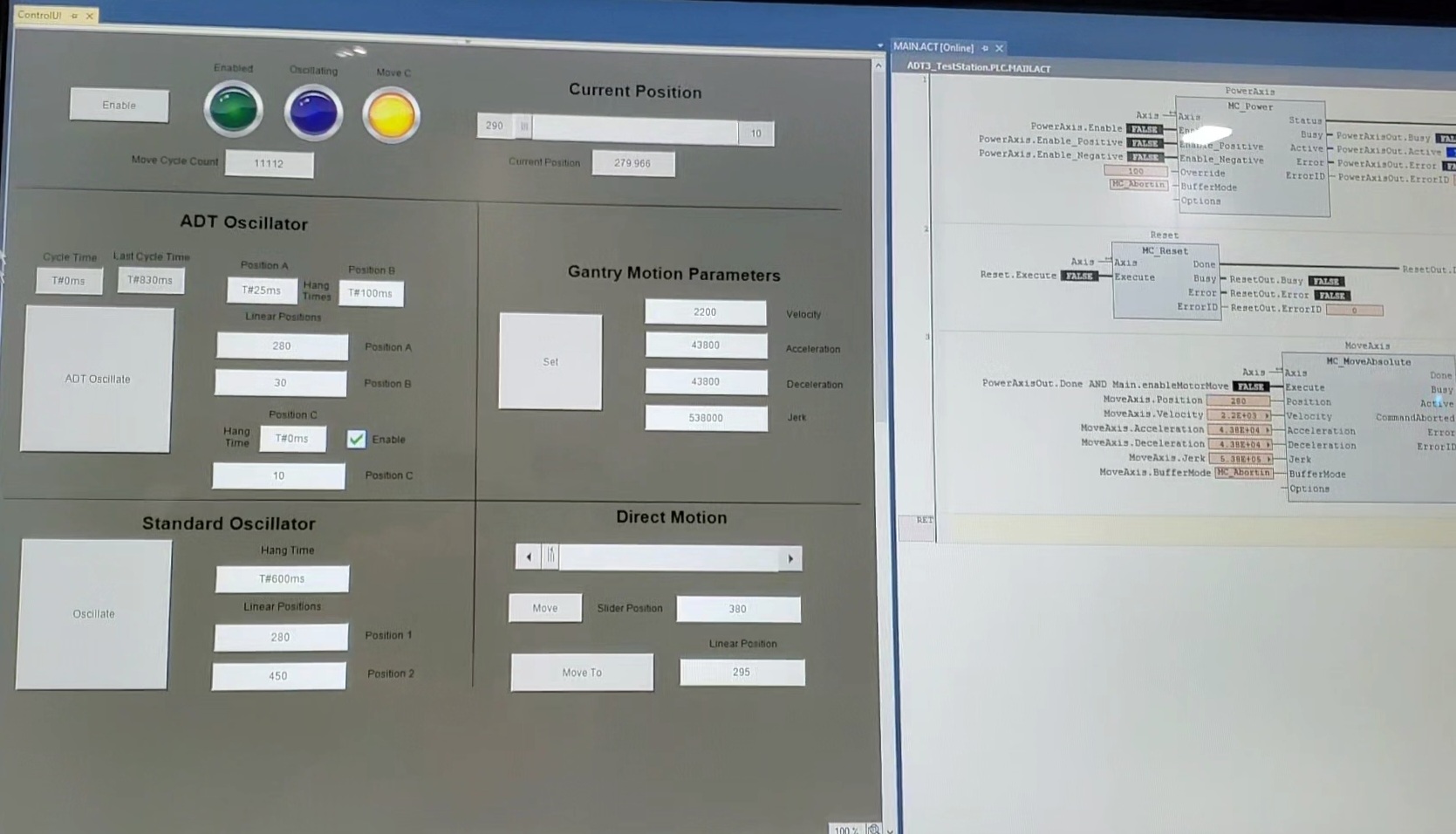

Linear Actuator GUI

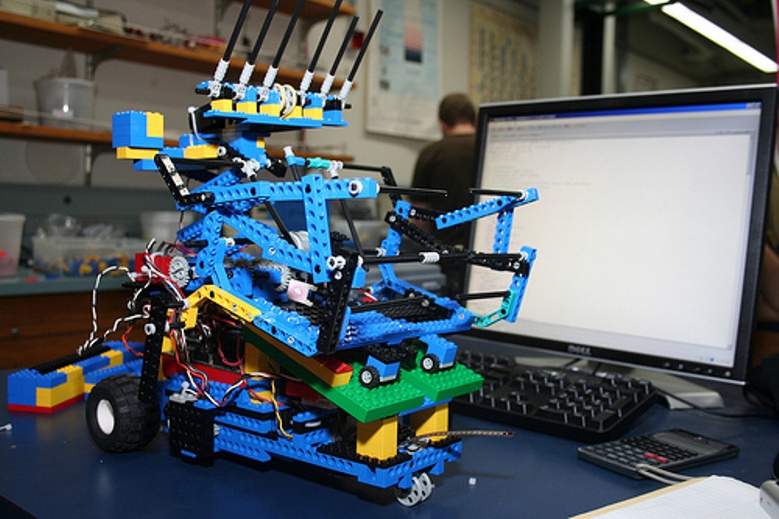

Mechatronics, Robotics, SoftwareAutomated Book Scanning Robot

Mechanical Design, Mechatronics, Robotics, SoftwareMQTT ChatBot Web Project

SoftwareAutonomous UAV

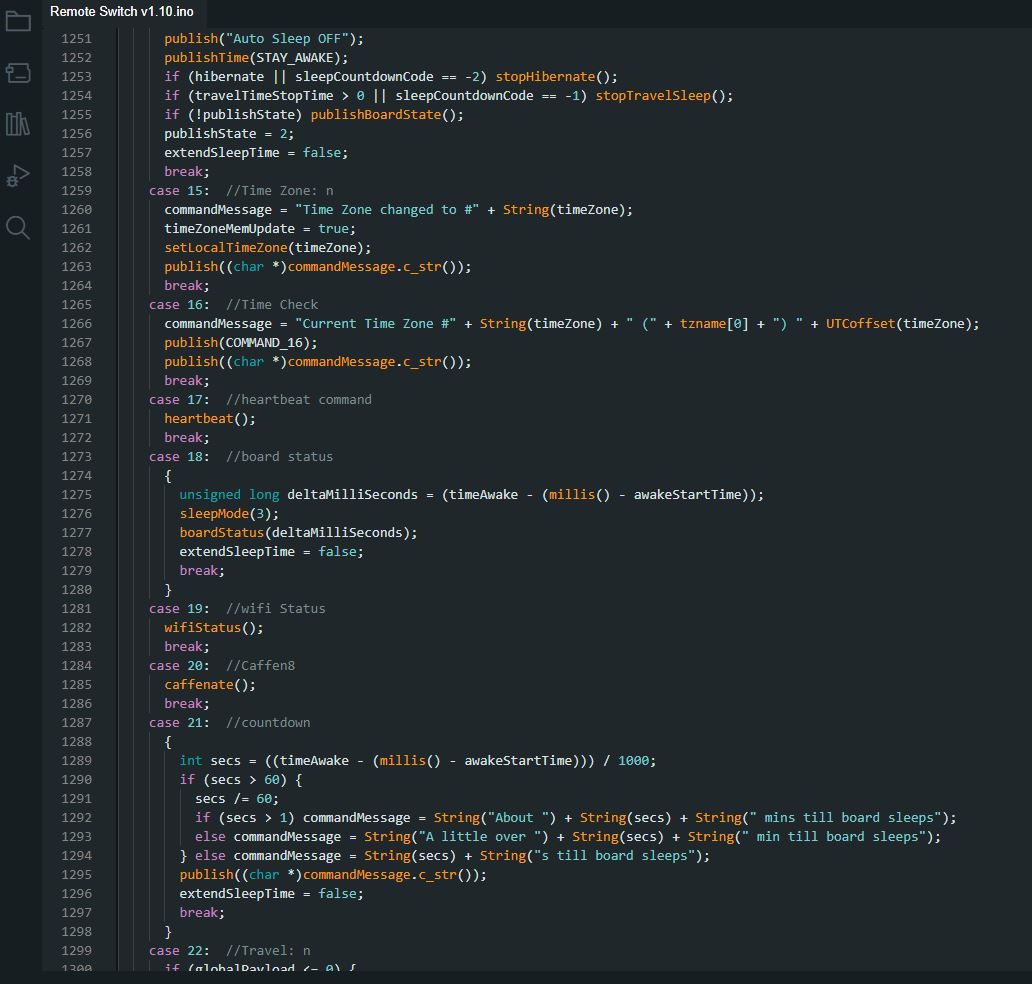

Electronics, Mechanical Design, Mechatronics, Robotics, SoftwareMQTT Client and Remote Switch

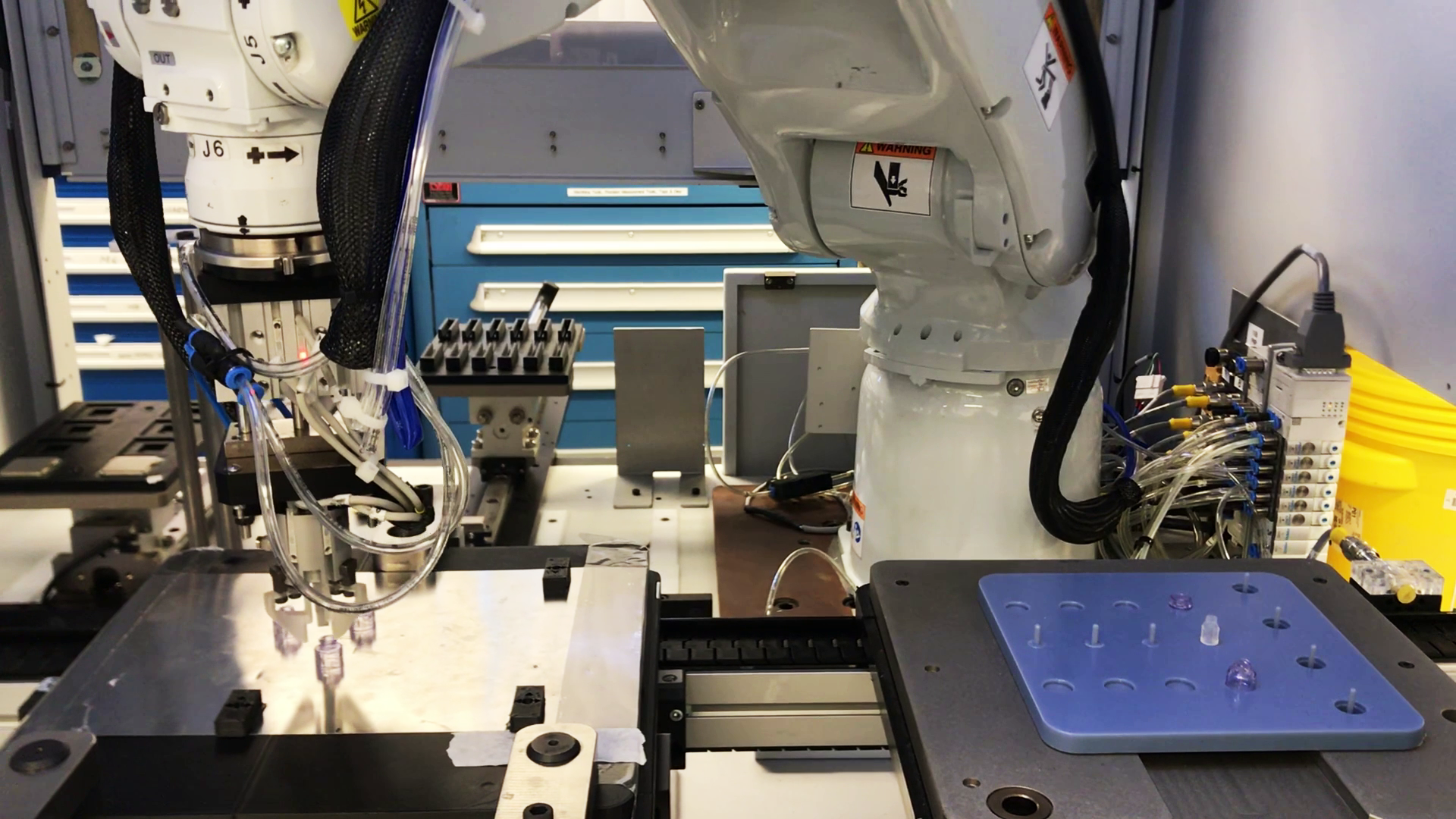

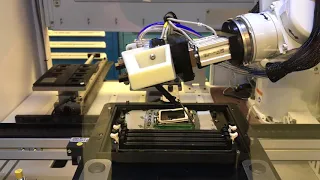

Electronics, SoftwareMachine Vision, Software, and Robotic Arms

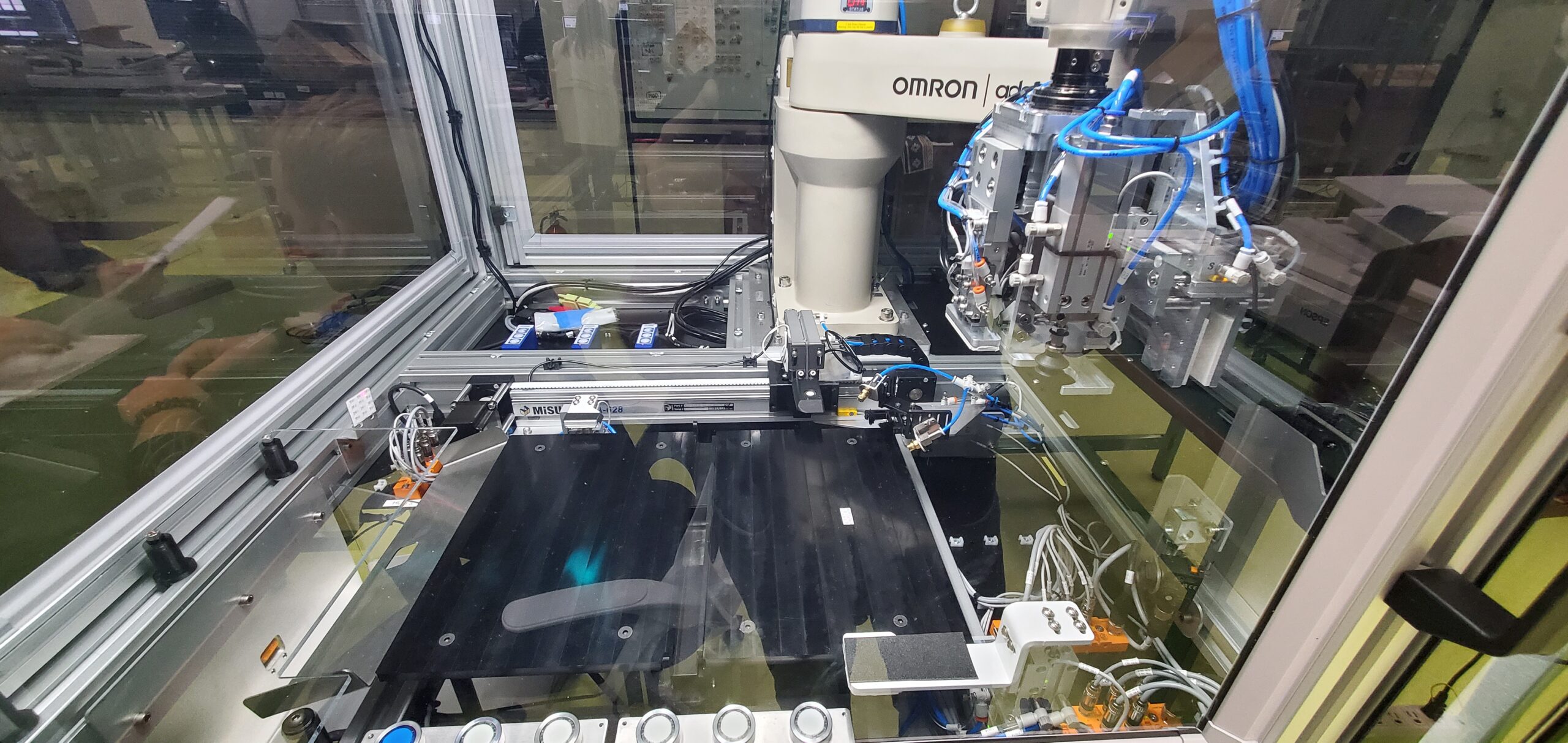

Mechatronics, Robotics, SoftwareMachine Vision and Multi-End Effector

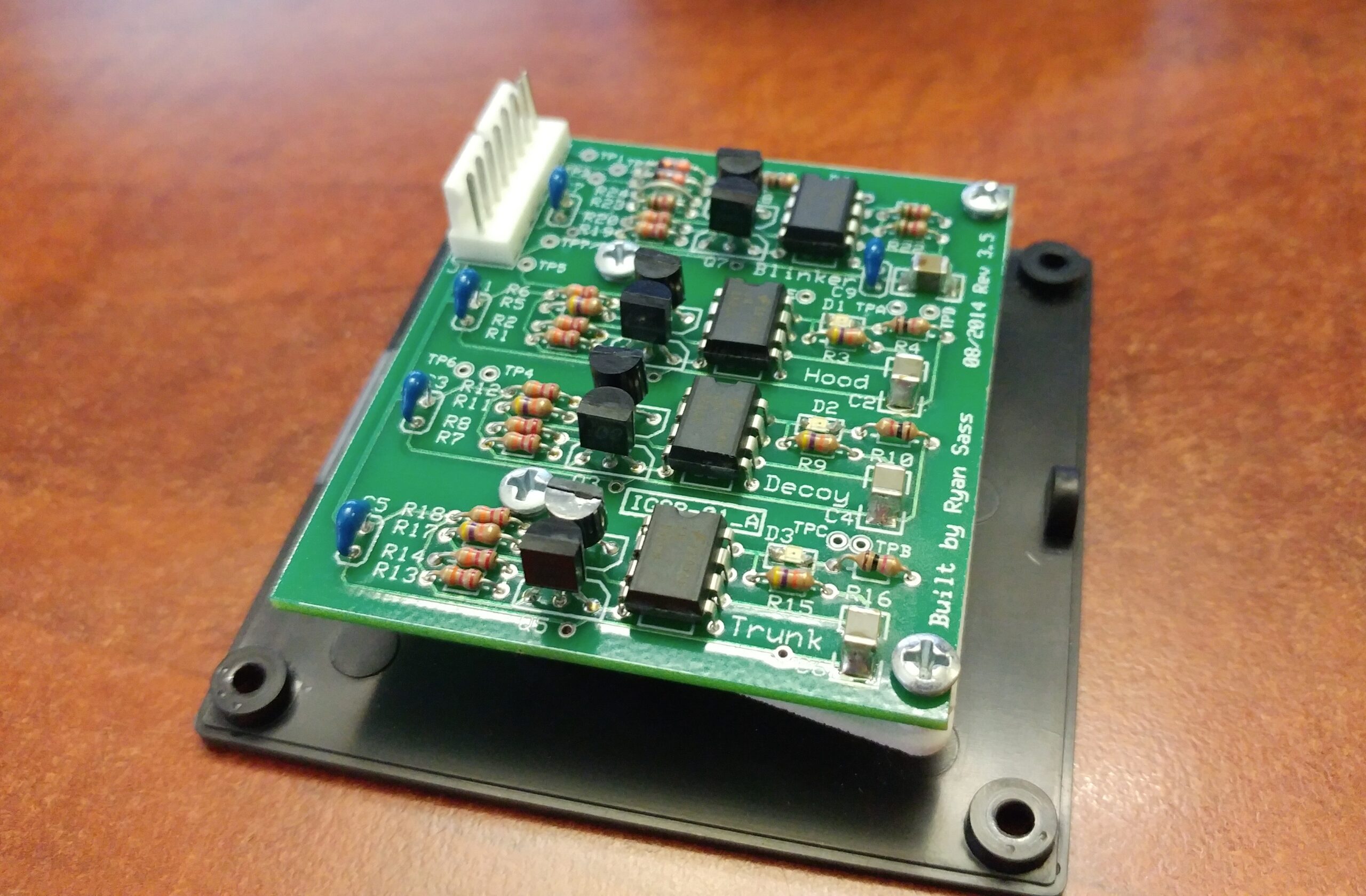

Mechanical Design, Mechatronics, Robotics, SoftwareCircuit Board, Multiplexer

ElectronicsSolidWorks Design Examples

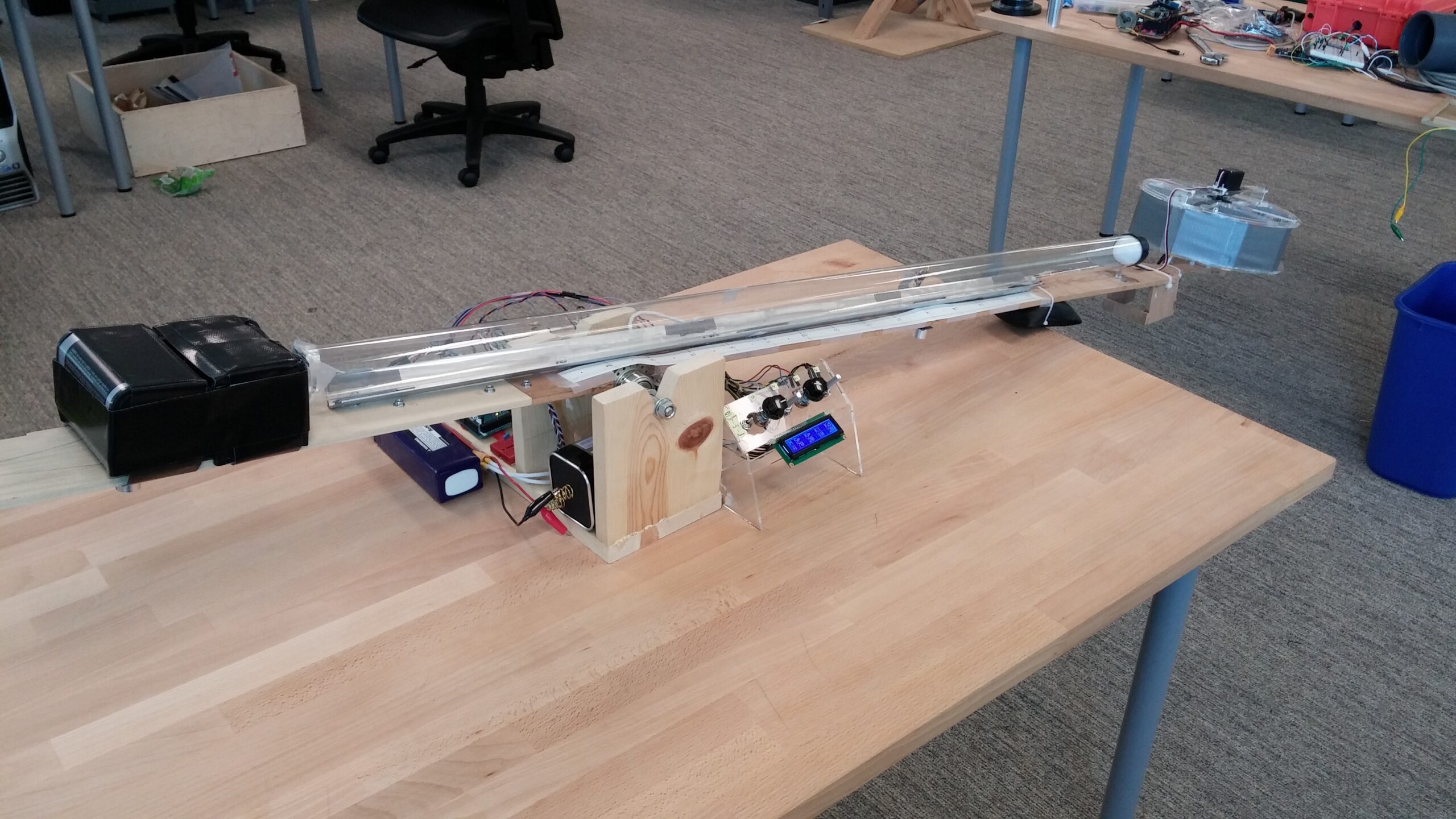

Mechanical Design, MechatronicsControl Loop System

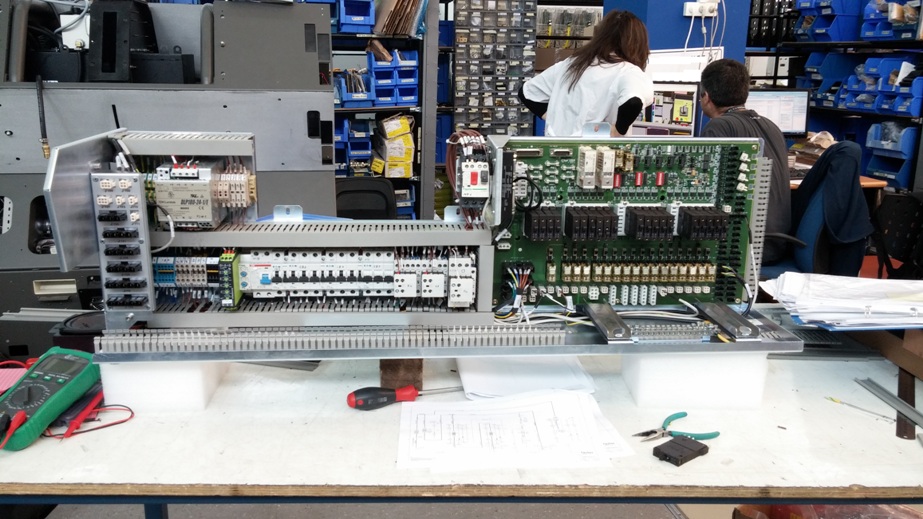

Mechanical Design, Mechatronics, SoftwarePower Distribution System

Electronics, SoftwareAutonomous Guided Vehicles

Mechanical Design, Mechatronics, Robotics, SoftwareManufactured Air Motor

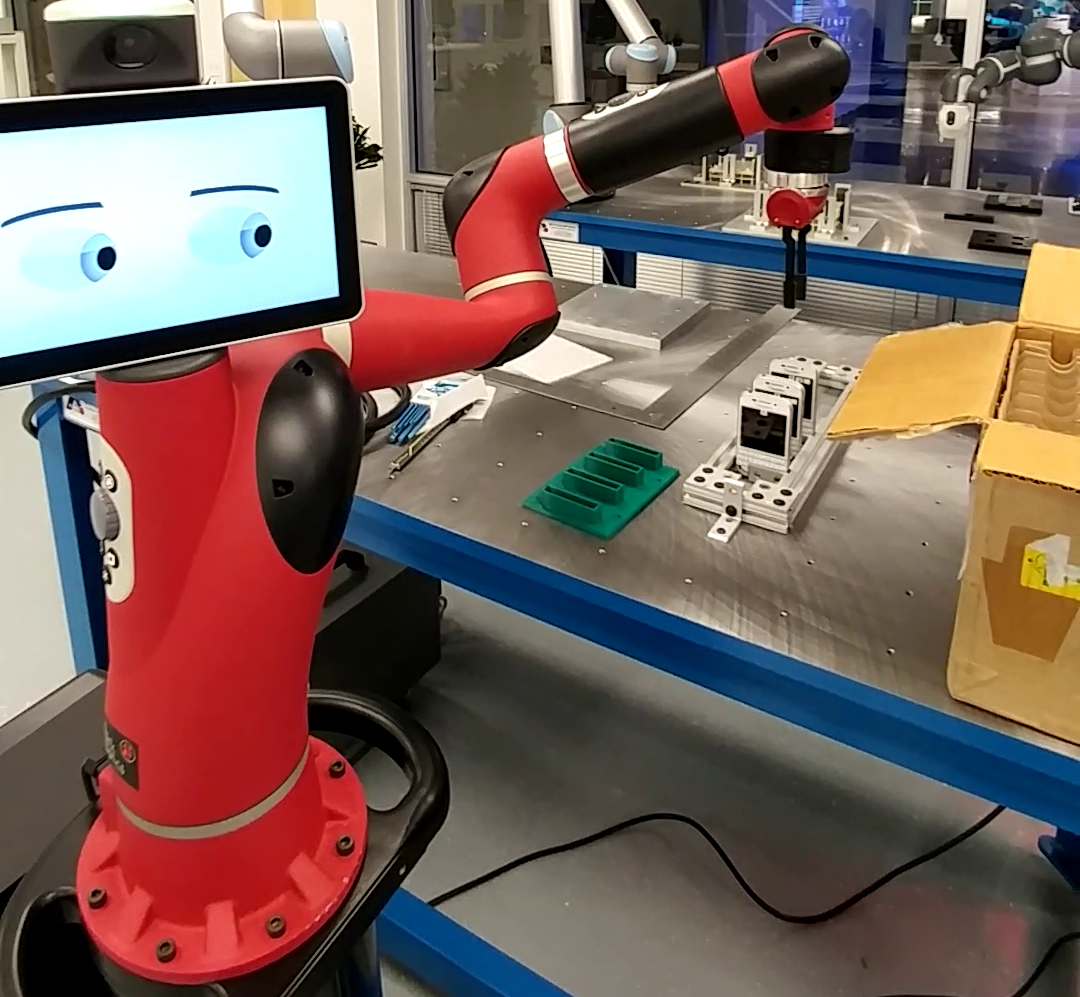

Mechanical DesignCollaborative Robotic Arms

Robotics, SoftwareWhat Colleagues Have To Say

I had the pleasure of working with Ryan directly at EaglePicher. He is a very personable, resourceful, and capable employee. Having known him for over 4 years, I can confidently say he has the technical know-how to excel both as a multi-role engineer and as a technical project manager. He tackled difficult task of managing a very complex and difficult project, including being directly involved in the engineering and production process and handling a wide range of team dynamics. Ryan would be a great asset to any team looking for technical aptitude and leadership.

Working with Ryan Sass does not feel like working. Ryan has excellent leadership skills, and he uses it demonstrate excellent task management as well as to motivate group members and even his students to work hard. He is definitely goal oriented, and inspires others to achieve goals in a timely manner. For Ryan, greatness isn't the end goal, it is the starting line. That means that there is no excuse for achieving anything less. Is there a part broken? Then fix it. Unfamiliar with a concept? Look it up. Part unavailable? Then lets build one. I have seen Ryan's "Yes I can" spirit engage students in the classroom, and I have felt it inspire me to work harder on our graduate projects together. Given the opportunity, I would definitely want to work with this guy on another project.

Working with Ryan has been an absolute pleasure. His positive attitude and resourcefulness were a welcome energy and addition to the development team. I refer to him as ‘the ninja’ because of his wide array and depth of skills, including SolidWorks expertise, technical project management ability, systems engineering capabilities, software and embedded firmware knowledge, mechanical design know-how, and presentation and communication finesse. Ryan is eager to tackle tough problems and won’t back down from speaking the truth tactfully in tough situations. I look forward to working with Ryan again and any team needing technical understanding and component leadership would greatly benefit from his abilities.

I had the pleasure to work with Ryan on various occasions both in Israel / USA and Brazil. Ryan is a skilled, open minded mechanical engineer with great insight and deep understanding. I can recommend him without hesitation, it's without doubt he is going to be a valuable asset in any project that falls in his field of expertise.

Ryan is motivated, communicative and talented. I recommended him to one of my favorite consulting clients who hired him (but then laid him off due to a cancelled NASA contract). I'm confident Ryan has continued to grow his skills and that he would make a very solid hire.

I heartily recommend Ryan Sass. I have worked closely for years with Ryan at Qylur, an advanced technology “start up” (check out the website). Ryan is talented in a variety of areas. Not only did he demonstrate his talent in mechanical engineering and cad, but he interfaced with the software development team on electronic hardware requirements, wrote sw code for motion control, wrote sections of technical manuals and coached field service on the functionality of the Qylar machine.

Skills Summary

Employment Timeline

2023 - Now

Ripcord, Inc.Senior Systems Engineer

Systems Engineering and Technical Project Management

2019 - 2023

EaglePicher, Inc.Senior Application Engineer

Lithium Battery Systems Project Analysis and Proposal Generation

2018 - 2019

EaglePicher, Inc.Technical Project Manager

Lithium Battery Systems Subcontractor

2017 - 2018

Jabil Circuit, Inc.Lead Automation Design Engineer

Factory Automation

2016 - 2017

Think Surgical, Inc.Mechatronics Engineer

Advanced Medical Product Development

2016

Jabil Circuit, Inc.Automation Engineer

Factory Automation, Contract Employment

2010 – 2016

Qylur Intelligent Systems, Inc.Mechanical Engineer

Mechatronics, Systems, and Assembly Lines

2009 – 2010

Alliant Techsystems, Inc.Analyst, Mechanical Engineer II

Space Structures and Components

Education

2016

Santa Clara UniversityM.S. in Robotics and Mechatronics

3.74 Major GPA, 3.80 Cumulative GPA

2009

University of California Santa BarbaraB.S. in Mechanical Engineering

3.82 Major GPA, 3.78 Cumulative GPA